ThermoDetector Infrared Thermal Imaging Monitoring Solution

Introduction to Scheme 1

ThermoInspector is an automated detection system used for thermal monitoring, analysis, and evaluation. It can be used for industrial control, security, quality control monitoring, and process monitoring and control in materials (such as plastics, metals, etc.), biological, chemical processes, and corresponding manufacturing industries, such as welding, heating, cooling, forging, biological fermentation, etc. It can measure, record, and evaluate thermal information in real time and be used in conjunction with existing machine control systems and PLCs.

The ThermoObserver system includes a central processing unit and can support up to 4 thermal imagers simultaneously. All thermal imagers use high sensitivity (better than 0.03 ℃) infrared thermal sensors, with a temperature measurement range of up to+2000 ℃. Due to these extraordinary characteristics, it can continuously measure and evaluate the thermal field on the surface of the tested product, whether it is plastic, metal, or biomaterial. Therefore, this system can check thermal characteristics such as thermal gradient, maximum or minimum temperature, as well as evaluate the dispersion of temperature along the thermal section, and check the rate of temperature rise in the selected area.

The ThermoObserver system includes a central processing unit and can support up to 4 thermal imagers simultaneously. All thermal imagers use high sensitivity (better than 0.03 ℃) infrared thermal sensors, with a temperature measurement range of up to+2000 ℃. Due to these extraordinary characteristics, it can continuously measure and evaluate the thermal field on the surface of the tested product, whether it is plastic, metal, or biomaterial. Therefore, this system can check thermal characteristics such as thermal gradient, maximum or minimum temperature, as well as evaluate the dispersion of temperature along the thermal section, and check the rate of temperature rise in the selected area.

Each ThermoDetector system supports multi camera thermal radiation measurement, camera control, color palette settings, temperature range settings, and defining more features. Users can choose different resolution cameras: 640 × 512, 336 × 256, 160 × 128, and also select lenses with different focal lengths.

2 Main technical features

·  Complete infrared thermal imaging visual solution

Complete infrared thermal imaging visual solution

·LWIR 640px, 336px, 160px resolution options available

·Plug and play installation and easy setup

·Powerful full screen visualization operation

·Graphics, tables, statistical data, OK/NOK indicator lights

·8x digital input/output interface, 4x Ethernet ports

·Powered by Ethernet cable and 24V DC power

·IP65 protection level and touch screen protection

·Temperature range -25 ° C~150°C, -40°C °C~550°C, the highest

optional2000°C

Three powerful central processing units

3.1 Touchscreen central control unit

·Industrial all-in-one machine solution

·Front panel IP65 protection level

·Quick and easy installation

·VESA interface

·Full HD touch screen display

·4-channel PoE Ethernet ports

·Alarm digital output

·Independent input trigger

·24V DC input power supply

·Provide 2 additional Ethernet ports for PLC

·serial communication

3.2 Passive central controller

ThermoObserver central controller uses a passive controller version to save size and cost, and is compatible with touch screen types

Same performance and interface. Users can use a full HD LCD display with a keyboard for system configuration integration. The size is only 26 x

The 22 × 8 cm passive controller is the world's smallest multi lens thermal imaging monitoring system.

4 System Control

4.1 Real time imaging

ThermoDetector automatically detects all infrared cameras. Users can set different color palettes, isotherms, and manual settings

Temperature range or change the temperature measurement range of the camera. The intuitive graphical interface facilitates checking user configuration and system integrity. Operator selectable

Choose different types of measurement tools (points, lines, rectangles, circles, etc.) and check the real-time data stream and values.

4.2 Image Evaluation

The ThermoInspector system can directly display all required data and information on the screen during monitoring operation. From real-time

Radiation flow (up to 4 thermal imagers), including analysis of the setting of each ROI (region of interest), time chart, temperature curve, and notification

Operator's digital indicator.

4.3 Alarm and Rule Settings

In actual production, operators should be able to set different analysis methods to cover various industrial application fields. ThermoInspector

Multiple measurement tools with locally adjustable emissivity are provided, and operators can also define statistical labels such as maximum and minimum values,

Mean, difference, median, etc. When the setting conditions are violated, the system displays an alarm and outputs a digital signal to the PLC.

Due to its user-friendly and configurable environment, ThermoInspector can start running in a very short amount of time. This system includes

Hundreds of equipped functions can be used for any type of application, and precisely because of this, integration does not require writing any additional algorithms.

5 application areas

5.1 Manufacturing Industry

·Plastic injection molding manufacturing

·Stability of flame spraying before mechanical spraying

·Critical temperature during laser welding

·The entire component during the final testing period

·Cutting and pressure tools overheat

·Material cooling and preheating

·Aluminum induction welding

·Metal brazing and sintering

·Adhesive or foaming, etc

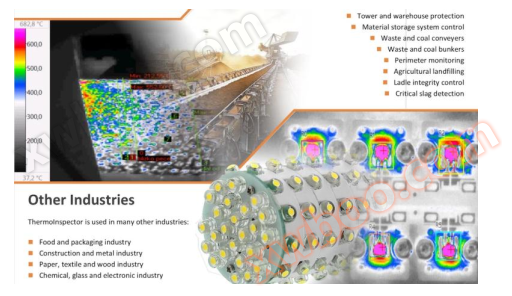

5.2 Safety and Fire Prevention

·Tower and warehouse protection

·Material storage system control

·Waste and coal conveyors

·Waste and coal warehouses

·Perimeter monitoring

·Agricultural landfill

·Steel ladle integrity control

·Key slag detection

5.3 Other industries

·Food and packaging industry

·Engineering and Metal Industry

·Paper, textile, and wood industries

·Chemical, glass, and electronics industries

·Agriculture, forestry, and ecological environment fields

·Physiological and ecological monitoring of animals and plants